Designing a compression spring involves several key steps to ensure it meets the required specifications for load, deflection, durability, and environmental conditions. Here’s a comprehensive guide on how to design a compression spring:

1. Define Requirements

Load Specifications:

- Maximum load the spring needs to support.

- Operational deflection (how much the spring will compress under load).

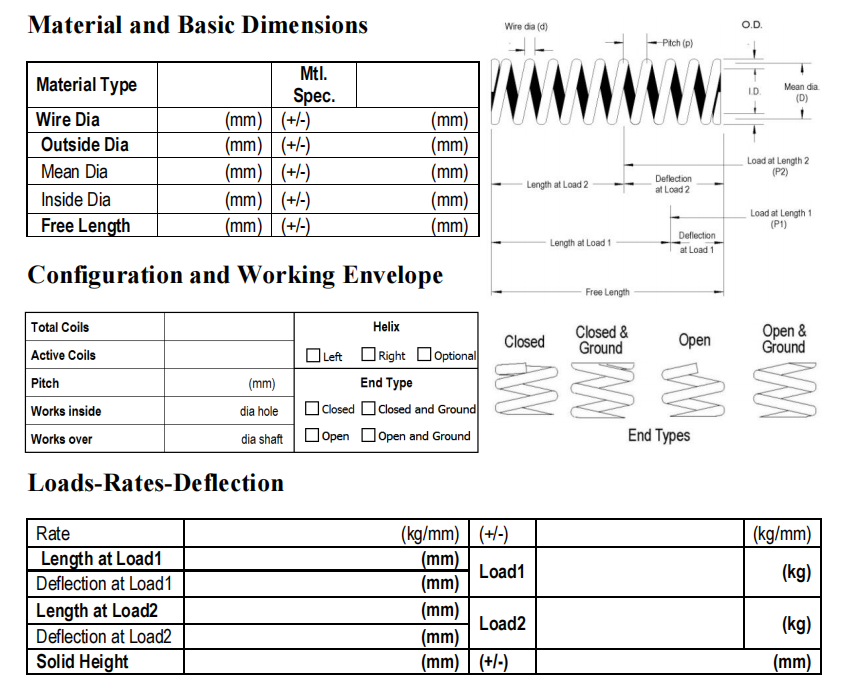

Dimensional Constraints:

- Free length (length of the spring without any load).

- Outer diameter and inner diameter constraints.

- Space available for the spring in the application.

Performance Criteria:

- Spring rate (stiffness) required.

- Desired fatigue life (number of cycles the spring must endure).

- Environmental conditions (temperature, corrosion resistance).

2. Select Material

Material Choices:

- Music Wire (High Carbon Steel): Commonly used for its high tensile strength and cost-effectiveness.

- Stainless Steel: Provides corrosion resistance.

- Alloy Steel: Offers enhanced strength and toughness.

- Exotic Alloys (e.g., Inconel): Used for extreme temperatures and corrosive environments.

3. Determine Key Parameters

Spring Rate (k):

- The stiffness of the spring, calculated ask=8D3NGd4

- G: Shear modulus of the material.

- d: Wire diameter.

- D: Mean coil diameter (average of outer and inner diameters).

- N: Number of active coils.

Maximum Load (F):

- The load the spring will bear, calculated usingF=k×ΔL

- ΔL: Deflection (change in length under load).

Solid Height (H):

- The length of the spring when fully compressed, calculated asH=(N+1.5)d.

4. Calculate Spring Dimensions

Wire Diameter (d):

- Choose based on required load and space constraints.

Mean Coil Diameter (D):

- Calculated asD=2Douter+Dinner.

Number of Active Coils (N):

- N=Gd4ΔL8FD3.

Free Length (L):

- L=N⋅d+ΔL+initial_tension_if_any.

5. Validate Design

Stress Analysis:

- Calculate the maximum shear stress usingτ=πd3K8FD

- K: Wahl correction factor for spring curvature.

Safety Factor:

- Ensure the design includes an appropriate safety factor based on the material’s yield strength.

6. Create a Prototype and Test

Prototyping:

- Manufacture a prototype based on the calculated dimensions and material.

Testing:

- Perform load and deflection tests to verify the spring meets the design criteria.

- Conduct fatigue testing to ensure the spring can endure the required number of cycles.

7. Optimize Design

Finite Element Analysis (FEA):

- Use FEA to simulate and optimize the spring’s performance under load.

Adjust Parameters:

- Make necessary adjustments based on testing and simulation results.

8. Document Specifications

Technical Drawings:

- Create detailed technical drawings with all key dimensions and material specifications.

Manufacturing Instructions:

- Provide clear instructions for manufacturing processes, including coiling, heat treatment, and surface finishing.

By following these steps and adjusting parameters as necessary, you can design a compression spring that meets the specific requirements of your application. If you don't want to design it yourself, you can send your detail parameters to us, we would design it free for you.